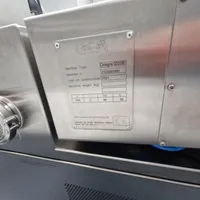

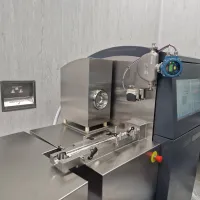

Used equipment for sale: GEA Continuous Mixing / Granulation System, Model ConsiGma GD25/80

Fluid Bed Dryers Processors

Specifications

More information about the GEA ConsiGma GD25/80

About the manufacturer GEA

GEA is a renowned company specializing in the manufacturing of heat exchangers, with a particular expertise in plate heat exchangers. With a rich history spanning several decades, GEA has established itself as a global leader in the industry, providing innovative and efficient solutions for heat transfer applications. Plate heat exchangers, one of GEA's flagship products, are highly efficient devices designed to transfer heat between two fluids while keeping them separate. These exchangers consist of a series of corrugated plates, which are stacked together and sealed with gaskets or welded to create alternating channels for the hot and cold fluids to flow through. The plates' corrugated design enhances heat transfer by creating turbulence and increasing the surface area available for heat exchange. GEA's plate heat exchangers are known for their exceptional performance, reliability, and versatility. They are widely used in various industries, including HVAC, refrigeration, food and beverage, chemical, pharmaceutical, and power generation. These exchangers offer numerous advantages, such as compact size, high heat transfer efficiency, low maintenance requirements, and the ability to handle a wide range of temperatures and pressures. GEA's commitment to innovation and continuous improvement is evident in their plate heat exchanger designs. They employ advanced technologies and materials to optimize heat transfer, minimize pressure drops, and ensure long-term durability. Additionally, GEA offers a comprehensive range of customization options, allowing customers to tailor the heat exchangers to their specific requirements. Beyond their exceptional product quality, GEA also provides comprehensive support services to their customers. This includes technical assistance, maintenance, spare parts supply, and training programs to ensure optimal performance and longevity of their heat exchangers. In summary, GEA is a leading global company specializing in the manufacturing of plate heat exchangers. With their cutting-edge designs, superior performance, and commitment to customer satisfaction, GEA continues to be a trusted partner for industries seeking efficient and reliable heat transfer solutions. ...read more

https://www.gea.com/en