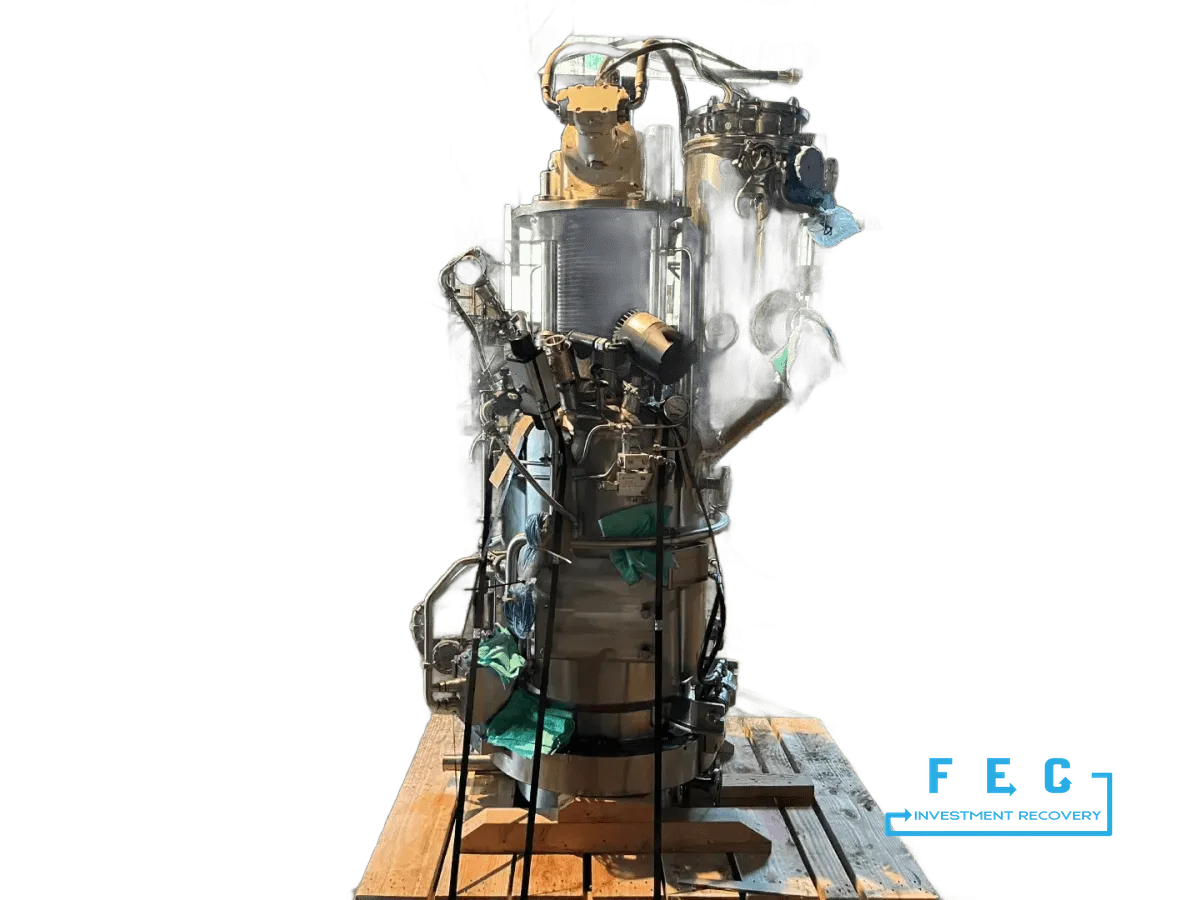

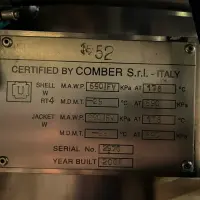

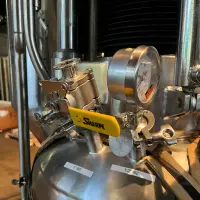

Used equipment for sale: 0.2 Sq Meter Comber Nutsche Filter Dryer, Hastelloy C22, Type PF100

Nutsche Filters

Specifications

More information about the COMBER PF100

About the manufacturer COMBER

COMBER is a specialized company known for its expertise in the design and manufacture of high-quality filtration equipment, particularly Nutsche filters. These filters are essential in various industrial processes, especially in the chemical, pharmaceutical, and food industries, where they are used for solid-liquid separation. COMBER's Nutsche filters are renowned for their robust construction, efficiency, and reliability. They are designed to handle challenging filtration tasks, offering solutions that ensure optimal performance and product purity. The company's filters are typically used in applications requiring precise control over the filtration process, such as in the production of active pharmaceutical ingredients (APIs), fine chemicals, and specialty chemicals. The company prides itself on its innovative approach, continuously improving its products to meet the evolving needs of its clients. COMBER's Nutsche filters are customizable, allowing them to be tailored to specific process requirements, including pressure, temperature, and material compatibility. This flexibility ensures that clients receive a filtration solution that is perfectly suited to their operational needs. In addition to manufacturing, COMBER provides comprehensive support services, including installation, maintenance, and technical assistance, ensuring that their clients can maximize the efficiency and lifespan of their filtration systems. With a commitment to quality and customer satisfaction, COMBER has established itself as a trusted partner in the filtration industry. ...read more

https://www.heinkel.com/brands/comber