Packaging is a crucial aspect of product distribution and protection, consisting of primary and secondary packaging. Primary packaging is the first layer that directly encases the product, providing protection and information, and often serving as the consumer-facing package. Examples include bottles, cans, blister packs, and wrappers. Secondary packaging groups primary packages together, facilitating handling, transportation, and storage. It often includes boxes, cartons, and shrink wraps. Case packers are machines used in secondary packaging to automate the process of placing products into cases or trays. They enhance efficiency, accuracy, and speed in packaging operations. Case packers can be categorized into several types, including top-load, side-load, and wrap-around packers, each designed to handle different packaging styles and product types. These machines are essential in industries like food and beverage, pharmaceuticals, and consumer goods, where high-volume packaging is required. The use of case packers reduces labor costs, minimizes human error, and ensures consistent packaging quality. However, they require significant initial investment and maintenance, and their operation may necessitate skilled personnel. Additionally, they may not be suitable for small-scale operations due to their cost and complexity.

packaging (primary and secondary) : case packers Manufacturers

MGS

MGS is a leading company specializing in the manufacturing of packaging solutions, with a particular

Filter

Main Categories

Categories

Sub Categories

Year of Construction

Manufacturers

Models

Locations

Year of construction

Voltage

Serial number

Blueprints

Manuals

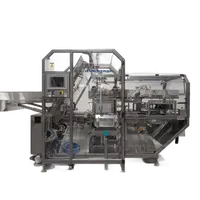

MGS Case Packer, Model Advantage

Used MGS case packer, model Advantage with powered case feeder, dual tag heads, PLC controls with HMI, 230 volt, serial# 12727, built 2008.

MGS - Advantage