Packaging refers to the materials used to enclose and protect products during storage, transportation, and sale. It serves multiple purposes, including preserving the quality and integrity of the product, providing information to consumers, and facilitating the handling and distribution process. Packaging can be categorized into primary and secondary packaging. Primary packaging is the immediate layer of packaging that directly comes into contact with the product. It is designed to contain and protect the product from external factors such as moisture, light, and physical damage. Examples of primary packaging include bottles, cans, blister packs, pouches, and jars. The primary packaging is often designed to be visually appealing and informative, as it is the first thing consumers see when they encounter the product. It may also include features such as labels, instructions, and branding elements. Secondary packaging, on the other hand, refers to the outer layer of packaging that holds and protects multiple units of the product. It is typically used for grouping and transporting primary packages. Secondary packaging can include items like cardboard boxes, shrink wrap, cartons, and trays. Its main purpose is to provide additional protection during transportation and storage, facilitate handling and stacking, and enable efficient distribution. Packaging feeders are devices used in packaging lines to automate the process of feeding products into primary packaging containers. They are designed to handle a wide range of products, such as bottles, tubes, pouches, and cartons, and ensure their accurate and efficient placement into the packaging. Packaging feeders can use various mechanisms, including conveyor belts, robotic arms, and vibratory systems, to feed the products into the packaging containers. These feeders help increase the speed and accuracy of the packaging process, reduce labor costs, and minimize the risk of product damage or contamination. In summary, packaging plays a crucial role in protecting and presenting products to consumers. Primary packaging directly contains the product, while secondary packaging provides additional protection and facilitates distribution. Packaging feeders automate the process of feeding products into primary packaging containers, enhancing efficiency and accuracy in the packaging line.

packaging (primary & secondary) : packaging: feeders Manufacturers

Hoppmann

Hoppmann is a leading company specializing in the manufacturing of packaging solutions, with a prima

Uhlmann

Uhlmann is a leading company in the packaging industry, specializing in the design and manufacturing

Filter

Main Categories

Categories

Sub Categories

Year of Construction

Manufacturers

Models

Locations

Year of construction

Serial number

Uhlmann Capmatic Sobstar Pouch Desiccant Feeder

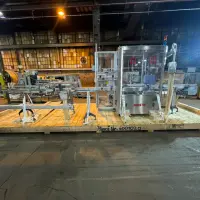

Unused Uhlmann Capmatic pouch desiccant feeder, model SorbStar Sachet, servo driven feed screw, automatic reject station, with dry air filtration system, with change parts for 45mL bottle, CE rated, HMI controller, project# 999107117, built 2020. Unit still in original shipping crate from manufacturer.

Uhlmann - SorbStar

Hoppmann Centrifugal Bowl Feeder, Model VFS301RLASA01

Used Hoppmann centrifugal scalloped bowl feeder, model VFS301RLASA01, 30" diameter, stainless steel sides, description FS30-IL SS AC W/slotted bowl with stainless steel hopper elevator, outfeed conveyor, control panel with Allen Bradley Micrologic 1200 PLC controls, serial# VFS301RLASA0101, built 2007.

Hoppmann - VFS301RLASA01