Packaging inspection equipment refers to the tools and machinery used to inspect and ensure the quality and integrity of primary and secondary packaging materials in various industries. Primary packaging refers to the immediate container that comes into direct contact with the product, such as bottles, cans, or blister packs. Secondary packaging, on the other hand, refers to the outer packaging that holds the primary packaging together, such as boxes or cartons. There are several types of packaging inspection equipment available, each serving a specific purpose. One common type is vision inspection systems, which use cameras and image processing software to detect defects or inconsistencies in packaging materials. These systems can identify issues like missing labels, incorrect barcodes, or damaged packaging. Another type of inspection equipment is the fill level inspection system, which ensures that the correct amount of product is filled into each package. This equipment uses sensors or weight measurement systems to detect underfilled or overfilled packages, ensuring compliance with regulations and preventing product waste. Seal integrity inspection equipment is also crucial in ensuring the quality of packaging. These systems use various methods like visual inspection, pressure testing, or vacuum testing to detect any leaks or improper seals in packaging materials. This is particularly important for products that require airtight or tamper-evident packaging. Overall, packaging inspection equipment plays a vital role in maintaining product quality, safety, and compliance. By detecting and preventing defects or issues in primary and secondary packaging, these systems help to ensure that products reach consumers in optimal condition.

packaging (primary & secondary) : inspection equipment Manufacturers

Brevetti CEA

Brevetti CEA is a renowned company specializing in the design and manufacture of advanced inspection

KEY TECHNOLOGIES

Key Technologies is a leading company specializing in the design and manufacturing of advanced inspe

Machine Vision Tech

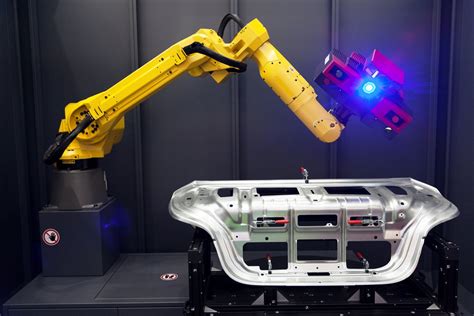

Machine Vision Tech is a leading company specializing in the development and manufacturing of cuttin

Optel

Optel is a company that specializes in providing advanced inspection and traceability solutions for

Seidenader

Seidenader is a renowned company specializing in the development and manufacturing of high-quality i

Sensum

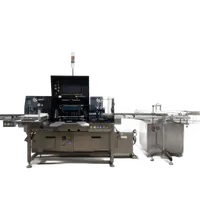

Sensum is a leading company specializing in the design and manufacturing of packaging inspection equ

Stevanato Group

Stevanato Group is a prominent global provider of integrated solutions for the pharmaceutical and he

Filter

Main Categories

Categories

Sub Categories

Year of Construction

Manufacturers

Models

Locations

Year of construction

Size parts available

Serial number

Fill materials

Chamber inserts

Product inspected

Blueprints

Manuals

Seidenader Vial Inspection Machine MS-60

Used fully automatic vial inspection machine, model MS-60. Production speed up to 600 products per minute. 60 position product-carousel. Loop mode for the inspection carousel. Set up for 2R vials, 16mm diameter. Includes: - Vacuum pump with V2A noise reduction cover- B&R PLC- HMI operator interface- Audit trail- Graphic counter display- Counter trend- Split timing screw with special closing m...

Seidenader - MS-60

Brevetti Vial Inspection Unit, Model A1

Used Brevetti vial inspection unit, model A1, speeds up to 360 pcs/hour, currently set up for 53.5 mm diameter 100 mL vails, 8mm - 95 mm diameter x up to 240 mm high vial size range, with integrated robotic arm, (4) inspection units, with vial feed infeed and acceptable exit tables, dual reject stations, with HMI panel, serial# BM242, built 2016.

Brevetti CEA - A1

Stevanato Group PWL Series Visual Inspection Machine

Used Stevanato Group visual inspection unit, model PWL LVP, for inspection of glass and plastic containers, serial# 21690097, built 2021.

Stevanato Group - PWL LVP

Optel Vision System, Model OP300

Used Optel vision system, model OP300, main unit has single camera inspection area and 3-camera surround inspection area, with (2) satellite inspection stations with portable barcode readers, includes spare parts and cameras, main unit serial# OP6307-02, built 2016.

Optel - OP300

Sensum Tablet Inspection Machine, Model SPINE-073

<p>Used Sensum tablet inspection machine, model SPINE, designed for inspection of complete surface of tablets, including engraving, speeds up to 360,000 tablets/hour for round and oblong plain tablets, 240,000/hour for engraved round tablets, 300,000 tablets/hour for oblong engraved tablets, with stainless steel product hopper and integrated operator HMI, 230 volt, 60 hertz, CE design, serial# 073...

Sensum - SPINE

Key Technology Inspection Machine, Type VS02-07702

Used Key Technology VeriSym SE optical inspection unit, model VS02-077702, with HMI touch screen, 220 volt, CE rated, serial# W1118592, built 2019.

KEY TECHNOLOGIES - VeriSym SE

Machine Vision Tech Tablet Inspection System, Model 360

Used Machine Vision Tech tablet inspection unit, model 360, dual camera's, feed hopper with vibrating bowl feeder, Allen Bradley Micrologix 1200 plc controller with operator interface cabinet, serial# 360-17163, built 2006.

Machine Vision Tech - 360