Capsule fillers, also known as encapsulators, are machines used in the pharmaceutical and nutraceutical industries to fill empty capsules with powdered or granulated substances. These substances can include active pharmaceutical ingredients (APIs), vitamins, minerals, herbal extracts, and other dietary supplements. Hard gel capsule fillers are specifically designed to fill hard gelatin capsules, which are made from gelatin derived from animal sources. These capsules consist of two halves, a body and a cap, that are joined together to enclose the contents. The capsule filler machine automates the process of filling these capsules, ensuring accuracy, efficiency, and consistency. The process of filling hard gel capsules involves several steps. First, the empty capsules are loaded into the machine's hopper. The machine then separates the capsules, fills them with the desired substance, and finally joins the two halves together to form a complete capsule. The filled capsules are then discharged for further processing or packaging. Hard gel capsule fillers are equipped with various mechanisms to ensure precise filling. These mechanisms include dosing systems, which control the amount of substance filled into each capsule, and tamping pins, which compact the powder to ensure uniformity and prevent air pockets. The machines can also incorporate additional features such as capsule polishing, sorting, and rejection systems to enhance the overall quality of the filled capsules. In summary, hard gel capsule fillers are specialized machines used in the pharmaceutical and nutraceutical industries to automate the process of filling hard gelatin capsules with powdered or granulated substances. These machines ensure accuracy, efficiency, and consistency in the encapsulation process, ultimately producing high-quality capsules for oral consumption.

capsule fillers / encapsulators : hard gel capsule filler Manufacturers

3P Innovation

3P Innovation is a leading company in the pharmaceutical industry that specializes in the design and

Bosch

Bosch is a leading manufacturer of capsule fillers and encapsulators, specializing in hard gel capsu

Capsugel

Capsugel is a renowned company specializing in the manufacturing of capsule fillers and encapsulator

Harro Hofliger

Harro Hofliger is a leading manufacturer of capsule fillers and encapsulators, specializing in hard

IMA

IMA is a leading company specializing in the manufacturing of capsule fillers and encapsulators, wit

Filter

Main Categories

Categories

Sub Categories

Year of Construction

Manufacturers

Models

Locations

Size parts available

Serial number

Fill materials

Chamber inserts

Sort field

Manuals

Year of construction

Voltage

Change Parts

Blueprints

IMA Practica 100 Intermittent Motion Capsule Filler

IMA Practica 100 capsule filler, SN PM4109. delivered with size "0" change parts. Demonstration machine. PRACTICA 100 is an intermittent motion capsule filling machine designed for filling hard gelatin or vegetable capsules with powder/granules or pellets. The extreme easiness of use is the main feature of the machine: PRACTICA has been designed to be used with simplicity and reduced mainten...

IMA - Practica 100

Capsugel Xcelodose XD600 Capsule Filler

Capsugel Xcelodose 600 Capsule Filler with Xcelotable, CE rated, serial# 600-1-039.

Capsugel - Xcelodose 600

Used MG2 capsule fillter, model Futura, with bead turrent, multiple size change parts including 1, 2, 3, 4 tooling, CE rated, serial# 5204, built 1997.

MG2 - Futura

Bosch Capsule Filler, Model GKF1400

Used Bosch capsule filler, model GKF1400, with liquid and mini tab filling heads, size 00 change parts, 230 volt, CE rated with controls, MS200701, serial# 701512, built 2008.

Bosch - GKF1400

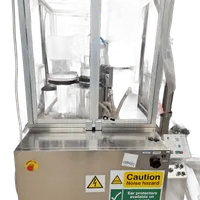

3P Innovation Dosator Powder Suitability Tester

Used 3P Inovation Dosator system, designed to replicate commercial scale processes to assess powder fomulation suitability, serial# 004.

3P Innovation - Dosator

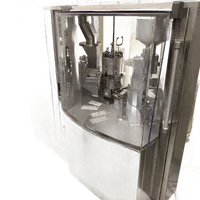

Harro Hoefliger Capsule Filler, MODU-C

Used Harro Hoefliger capsule filler, model MODU-C, with trolley dosing system, CE rated, 400 volt, 50 Hz, serial# HH-0006.014, built 2007.

Harro Hofliger - MODU-C

IMA Zanasi 6F Automatic Capsule Filler

Used IMA Zanasi automatic capsule filler, model 6F, speeds up to 6,000 capsules/hour, set for powders with size 0, 1, 2, 3 and 4 tooling, CE rated, 220 volt, serial# 35054, built 2003

IMA - 6F

IMA Zanasi 40F Capsule Filler

Used IMA Zanasi 40F capsule filler with change parts for capsule sizes 3 and 4. Unit requires 220 voltage, missing vacuum pump, will supply machine with one set of change parts, current available inventory of change parts for this machine are 1, 3, and 4, none with alignment tooling.

IMA - 40F

MG2 Futura Capsule Filler

Used MG2 MG Futura capsule filler designed for powder and liquid filling with an output range of 6,000 to 48,000 capsules per hour. Size 1 and 4 change parts. Unit requires 480 volt electricity. Serial# 5228, built 1998.

MG2 - Futura

Capsugel Xcelodose 120 Capsule Filler

Used Capsugel Xcelodose 120 capsule filler with controller and associated tooling. Unit is CE rated, serial# 120-1-006, built 2008. As Is.

Capsugel - Xcelodose 120